Loading...

Loading...

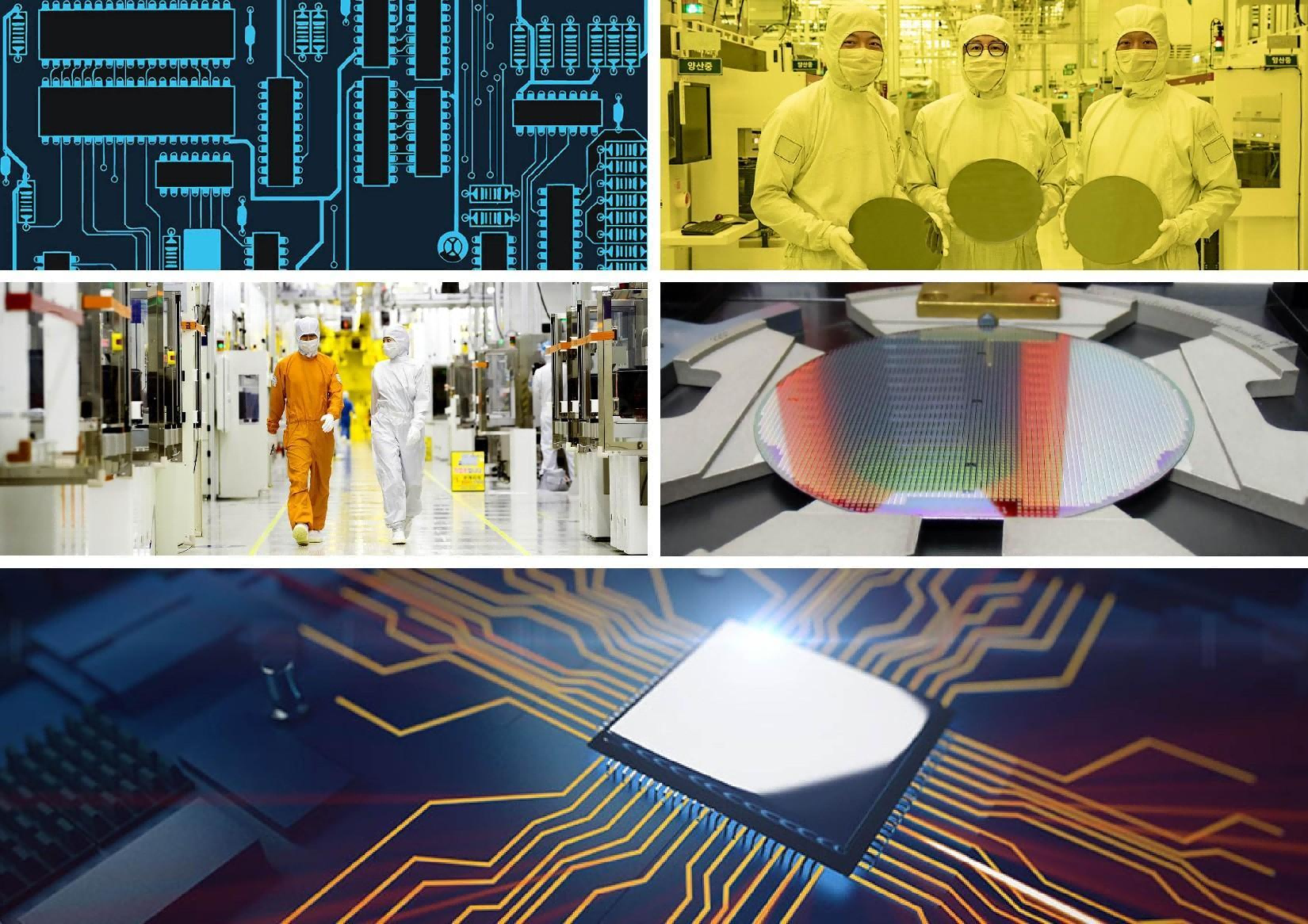

While the average semiconductor chip may deceive you with its fingernail-sized form factor it’s packed with billions of electronic components, from transistors to diodes, resistors, capacitors, and more. All these elements must work together in perfect harmony to perform logic operations and store data. So, what does it take to manufacture this kind of circuit? And how does a business like Samsung produce these complex components at such scale? In this eight-step article, I’ll be providing a ‘quick-start’ guide to semiconductor fabrication and answering a few of the most asked questions about the manufacturing process for today’s integrated circuits (ICs).

Step 1: Building and protecting the silicon wafer To engineer a chip, microscopic circuit patterns are built on multiple layers of various materials in a process repeated at least a few hundred times. The wafer is like the chip’s ‘canvas’. It’s a thin, glossy disc that’s cut using specific diameters. Most wafers are made from silicon, which is extracted from sand, purified and then solidified into an ingot. Before it’s completely cooled, the cone-shaped ends of the ingot are cut off while the body is sliced into wafers of uniform thickness. The bigger the wafer, the higher the productivity. Some pub quiz trivia for you: The largest wafer diameter used in semiconductor fabrication today is 12 inches. Abrasive chemicals and machines polish the uneven surface of the wafer for a mirror-smooth finish that will allow circuit patterns to print better onto it. Then, a process of wet oxidation produces a smooth layer of silicon dioxide. This protects the surface of the disc from chemical impurities that can alter conductivity, damaging the circuit’s electrical properties.

Step 2: Imprinting the integrated circuit In an integrated circuit (IC), numerous transistors, diodes, resistors, and capacitors are seamlessly connected, and each plays a different role in processing and storing electric signals. To make this, a complex pattern is transferred using photomasks that capture its miniaturized version in what’s called the photolithography process. The circuit design is created with computer-aided design software and then duplicated onto a glass substrate made of ultra-pure quartz with a beam of electrons – and a photomask is born.

Step 3: The etching process The etching process in semiconductor fabrication uses a liquid or gas etchant to selectively remove unnecessary parts until the desired circuit patterns are left on the wafer surface. Even though it’s more costly and complicated, dry etching (also called plasma etching) is the more widely used technique as it produces a higher yield. To start, we need a plasma state. A radical atom dissociated from this plasma state becomes volatile and moves away from the wafer surface, peeling off surface material that was not previously coated and protected with photoresist.

Step 4: The thin-film process For a semiconductor chip to get the desired electrical properties, materials at atomic or molecular levels are densely piled up in a film so thin that highly elaborate tech is essential for even deposition. Let’s say we are forming a 1 micrometre-thick film on an 8-inch wafer. This would be the equivalent of evenly piling up sand 1mm thick on a 200-metre-wide schoolyard. Pretty high-tech, right? The methods of depositing these materials can be divided into physical vapour deposition (PVD) and chemical vapour deposition (CVD). The more common CVD method can be broken down into thermal, plasma-enhanced and optical CVD depending on the source of external energy used. The thin film fabricated through the deposition process gets categorized into metal (conducting) layers for electrical connections between circuits, and dielectric (insulating) layers that electrically isolate the internal layers, protecting them from contaminants. What comes next is the process of implanting ions in the form of fine gas particles on the deposited layer so that the semiconductors can develop electric properties.

Step 5: The metal interconnect process The metal interconnect process ensures the electronic elements are connected via metal circuits so that signals can reach where they need to. Great adhesiveness to silicon dioxide and high processability makes aluminium a popular substance for the metal interconnect process, although nowadays copper is getting in on the act thanks to its cost-effectiveness and better conductivity properties. Aluminium circuits are created through physical vapour deposition using plasma. When a mass of aluminium is boiled in a decompressed vacuum chamber, the chamber gets filled with aluminium particles. A wafer is then inserted into the vacuum chamber where the aluminium particles stick to it.

Step 6: The EDS Process When we’re about to complete the fabrication of our semiconductor, we need to look at the yield. This is the percentage of functional chips out of the total chips designed on a single wafer. Generally, the higher the yield, the higher the productivity, so it’s key for manufacturers to keep the yield rate high. Several factors are crucial here: the cleanliness of the cleanroom, the accuracy of the processing equipment and the conditions of each process. Semiconductor chips will then be subject to strings of tests including the electrical die sorting (EDS) test. The EDS process verifies that each chip that leaves the facilities meets the manufacturer’s standards. Defective chips are marked with a dot of ink and discarded.

Step 7: Packaging If the IC were the human brain, its packaging would be the nervous system and skeletal structure. Semiconductor packaging serves a variety of purposes: ensuring the inter-terminal connection, supplying electricity, and providing heat resistance and protection for the IC. The packaging also ensures protection from external factors, like humidity, chemicals, impact and vibration. First, wafers are cut into individual chips with a diamond cutter. Functional chips are placed on a lead frame or printed circuit board, which are then attached with balls that provide an electrical connection. The lead frame delivers electrical signals between the semiconductor chip and the board while offering structural support to protect the chip. After the chips are attached to the lead frames, they undergo the moulding process. At this stage, intense heat is applied to an epoxy moulding compound made of resin, which is liquefied and shaped into the desired external shell. Step 8: Testing Once packaged, we need to check the chip works properly. Chips are tested under various conditions of voltage, electrical signals and temperature. This way, we can measure their electrical and functional characteristics as well as their performance to detect any defects. At Samsung, we collect and analyse the data accumulated during the test and give feedback to the teams overseeing the manufacturing and assembly processes to improve product quality. Finally, the name of the IC, date and origin of manufacture, product characteristics and serial number are printed on the product. A better future for chips Right now, the business of producing semiconductor chips is a complex process. But innovative manufacturers are leading the charge toward a sustainable and future-proofed chip supply. Pioneering methods in manufacturing, sustainability and power-saving are the keys to this process. By working collaboratively with the industry, Samsung is exploring innovations in these elements and overcoming the hurdles that surround them. For example, using cutting-edge High-K Metal Gate technology, we developed the industry’s first 512GB DRAM integrated chip to power the most extreme workloads in supercomputing, machine learning and data analytics applications.

Another technology milestone also emerged with our industry’s smallest, 14-nanometer, DRAM based on extreme ultraviolet (EUV) technology which enables the achievement of the highest bit density while enhancing the overall wafer productivity by approximately 20%. Most recently, we released the PM1743 – a high-performance 5.0 SSD that ushers in a new generation of solid-state storage. The innovative device enables superfast processing of vast amounts of data to coincide with the increasing popularity of AI services and the metaverse. In an age of automation, connectivity and AI, semiconductors will form the fabric of our future world.